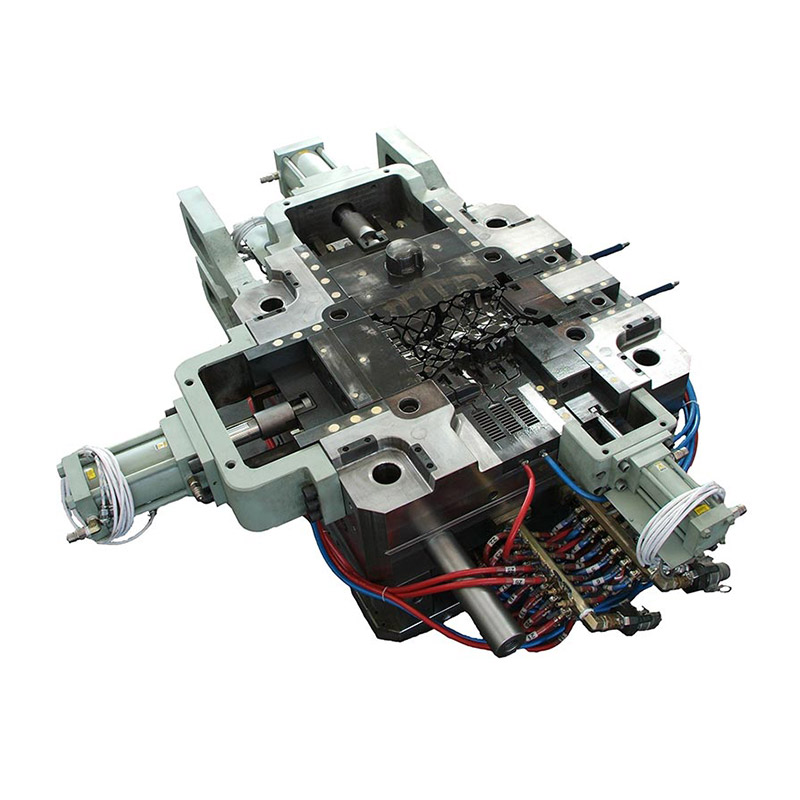

Aluminium Yakakwira Kudzvanya Kufa Kukandira Telecom Housing Tool Die Cast Mold

Basic Information

| Product name | High Pressure Die Casting Telecom Housing Mold |

| Mold Material | PH13,H13, DVA, DIEVAR, 8407, 8418, W400 nezvimwe. |

| Casting Alloy | Aluminium |

| Cavity Qty | Single Cavity, Multiple Cavity kana Combination Cavity |

| Tonnage | 200T-2000T |

| Kurapa | Kurapa Kupisa, Nitriding, Polishing nezvimwe. |

| Mold Life | 30000 shots, 50000 shots, 80000shots zvinoenderana nezvigadzirwa |

| Applications | 1. Zvikamu zvemotokari uye mudhudhudhu; |

| 2. Mwenje & mwenje zvikamu; | |

| 3. Zvikamu zvemagetsi zvemagetsi; | |

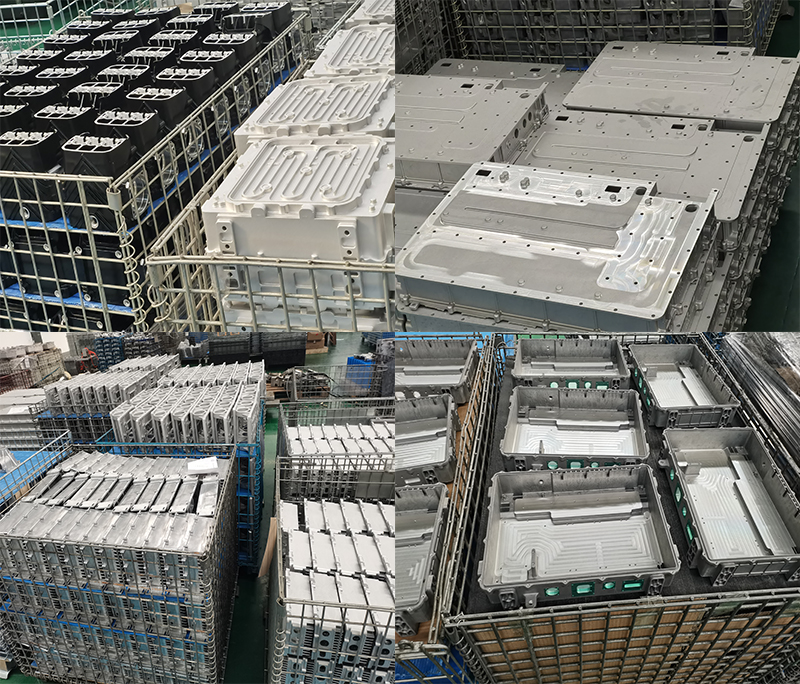

| 4. Telecom Zvikamu; | |

| 5. Industrial hardware uye Machine Sparepart; | |

| 6. Midziyo yemidziyo yemumba; | |

| 7. Zvikamu zvefenicha; | |

| Nguva Yekutungamira | 35-60 mazuva |

| Chikumbiro chakakosha | Maererano nechikumbiro chemutengi |

Tinogona kugadzirisa, asi kwete kugumira kune izvi:

Aluminium inofa ichikanda telecom imba mold

Aluminium die casting auto part mold

Aluminium die casting power tools mold

Aluminium die casting power tools housing mold

Aluminium inofa ichikanda auto gearbox imba mold

Aluminium die casting auto water pump housing mold

Aluminium die casting light housing mold

Aluminium inofa ichikanda kupisa sink mold

Kusanganisira zvimwe Aluminium Yakakwira Kudzvanya Die Kukanda Zvishandiso.

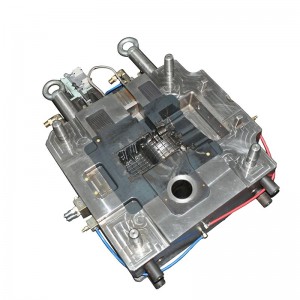

FENDA Aluminium Die Casting Mold Manufacturing Processs

Matanho makuru ealuminium alloy yedu anofa achikanda mold maitiro ndeaya: CNC Milling process, Heat Treatment, EDM process, WEDM process, Polishing, uye Assembling.

CNC Milling Process

Nhanho yekutanga yealuminium die casting mold kugadzira: shandisa yakakwira yekumhanyisa machining nzvimbo kukuya mhango ye mold, ichisiya machining mvumo inosvika mirimita imwe yechimiro chechigadzirwa.Ndeyeimwe deformation mushure mekurapwa kwekupisa.

Mushure mekugadzira kwekutanga, iyo mold cavity ichatumirwa kunopisa kurapwa.

Kana mapango adzoka mushure mekurapwa kwekupisa, machining echipiri anozoitwa.Isu tinodaidza nzira iyi yakanaka machining.Panguva ino, saizi yese inoenderana nedhizaini yekugadzira mold

EDM Maitiro

Mushure menguva mbiri dzekugadzira, kune dzimwe nzvimbo dzakaoma kucheka nekucheka kwepamusoro-soro, zvino dzichapedzwa neEDM.

Kune akawanda akadzika grooves uye akatetepa maburi uye akaomesesa mhango pamusoro pevhu, izvo zvakaoma kugadzirisa nemichina yekugaya.Izvi zvinoda EDM electric discharge machining.

Mukuwedzera, EDM inowanzoshandiswa kune zvimwe zvikamu zvinoda kunyanya kushandiswa kwepamusoro uye kuoma kwepamusoro.

WEDM Process

Nheyo yekushanda yeWEDM (waya yekucheka) ndeye kushandisa inoramba ichifamba yakaonda simbi waya (inonzi electrode waya) se electrode kuita pulse spark discharge pane workpiece kubvisa simbi uye kuicheka kuita chimiro.

Iwo maburi ejector mu mold, pamwe nemamwe anopinza-angled, maburi akasarudzika asingakwanisi kugadzirwa, uye zvishongedzo zvese zvinopedzwa nekucheka waya.

Mushure mekuita uku, mold cavity inokwenenzverwa.Uye yekupedzisira maitiro, unganidza iyo aluminium die casting mold, uye kuyedza-kunze.

Factory Profile

Fenda inokwanisa kugadzira uye kugadzira maturusi uye zvigadziriso zveese maitiro edu.

Simulation ongororo inobatsira mainjiniya edu kugadzira mamwe maturusi anoshanda.Mu-mudzimba die casting tooling workshop inobatsira mukusvika mutengi anotungamira nguva yekugadzira nekusimbisa.

Iyo yakanyanya pressure die casting process inonyatso ratidza nhanho yedu yekugona kugadzira.Tine 7 advanced chamber die casting machines kubva pa400T kusvika 2000T mumusangano wedu wekukanda kufa, izvo zvinotitendera kuzadzisa zvinodiwa mumapurojekiti akasiyana siyana ekukanda aluminium kufa.

Yedu CNC machining Center, ine makumi masere seti epamusoro-kumhanya/yakanyanya-chaiyo machining nzvimbo, uye anopfuura makumi maviri seti epamusoro-chaiyo inomutsa friction welding, kurapwa kwepamusoro uye mimwe michina chaiyo chaiyo.

Fenda inopa emhando yepamusoro aluminium die casting parts uye zvikamu zveakasiyana maindasitiri anosanganisira mota, led lighting, telecommunication, michina, mishonga, pombi dzemvura, kudiridza, migodhi, petrochemical, magetsi, simba, aerospace, submarine nezvimwe.